Precision, reliability, and efficiency are the most important in the world of industrial automation. Out of the numerous elements contributing to these factors, timing belts are important in harmonizing the movement of mechanical components. A single specialized form is the double-sided timing belt, which has become very important to systems that need both-sided power transmission. Its distinct design enables it to push several pulleys at the same time and therefore is a useful application to intricate automation systems, with space saving and coordinated movement being a prerequisite.

In contemporary mechanical designs, when compactness and versatility are needed, double-sided timing belts provide a good solution to multi-axis power delivery. They include the benefits of a Double Sided Timing Belt with the additional benefit of bilateral operation, which does not require extra components or parallel drives. This invention helps in the smoothness of performance, ease of maintenance, and flexibility in designing the system.

Learning Timing Belts: Double-Sided

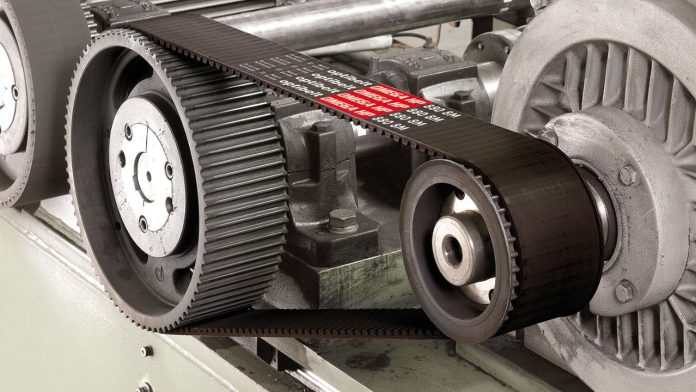

A two-toothed or a double-toothed belt is a type of timing belt with teeth on the inside and the outside of the belt. This type offers dual-direction power transmission, unlike a conventional timing belt that only conveys motion on one side, provided there is a toothed surface. The two teeth will be fitted to interact with two distinct pulleys, and more complex drive arrangements can be generated without extra belts and other parts.

These belts are normally built using high-strength materials like neoprene or polyurethane with tension cords of steel and fiberglass. This mix guarantees stability, flexibility, as well as the anti-stretching property even in harsh industrial environments. The teeth on each side of the belt may or may not be the same tooth; depending on the design requirements, they can be of different profiles to suit the particular pulley system being used.

Benefits of the Double-Sided Timing Belts

The most remarkable benefit of the two-sided timing belts is that they can be used to pass on the movement to more than one shaft using a single drive system. Their dual functionality is what makes them very useful in the small systems where space is minimal and when various mechanical devices need the perfect coordination among themselves.

The other high advantage is their accuracy. Due to the constructive interaction of the belt teeth and the pulley grooves, the slip is minimal, consequently, ensuring regular transfer of motion and timely transfer of motion. This is an essential feature of automation that demands precision of positioning, as in the case of robotic arms, conveyor systems, and printers.

Industrial Automation Uses

Industrial applications Industrial automation systems have a common use of double-sided timing belts in cases where components need to operate in synchrony. Among the most widespread ones is in conveyor systems, where the products should be transported on precise routes, and coordination should be observed between different parts. The upper and lower pulleys could be driven in balance with the help of a two-sided belt, which made the speed and movement of the various conveyors the same.

These belts allow complicated motion control in robotic systems in which various arms have to move opposite to each other. They are an efficient solution to compact robotic designs, having the ability to send power to two or more axes.

Maintenance and Engineering Design

When selecting the double-sided timing belt, one should take into account such factors as the load capacity, the pitch, the tooth profile, and the environmental conditions. The engineers are expected to ensure that the two sides of the belt are properly aligned with the two respective pulleys to prevent unnecessary wear and balance the tension. Checking the belt to determine whether worn out, cracked, or contaminated can also extend the service life of the belt.

These belts may be utilized such that they last long, but may easily be destroyed when not installed or taken care of. The tension cords of the belt can be minimized, and tension on the same can be minimized by making sure that the pulleys are correctly aligned and tension adjusted. It is possible to prevent tooth skipping. Cleaning and lubricating of surrounding parts frequently can also be beneficial in enhancing the life of belts, and maintaining them in the best operation.

Conclusion

The use of double-sided timing belts has become a necessity in contemporary industrial automation. Their capability to deliver synchronized power to multiple shafts, coupled with their small size and high accuracy, makes them a great option for diverse uses. These belts are very efficient, soundless, and dependable, no matter whether in conveyor systems, robotics, or printing machinery. With the further development of automation technology, the need for flexible and efficient power transmission options, such as double-sided timing belts, is likely to increase and establish itself as one of the primary aspects of industrial machinery in the future.