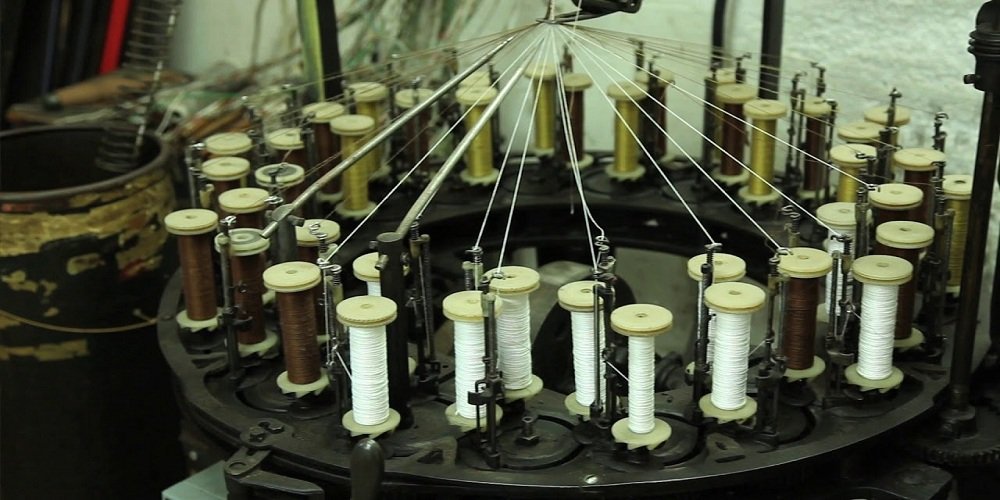

Introduction to Rope Braiding Machinery

The first mechanical braiding machine tool created during the Industrial Revolution was a rope braiding machine. A braiding machine is a tool that weaves three or more strands of yarn or wire together to produce various materials, such as rope and some varieties of lace. Materials for braiding include leather tapes, metal wires, natural and synthetic yarns, and others. Alibaba has been a market leader in providing rope braiding equipment for many years. This success can be attributed partly to Alibaba has suppliers with extensive experience in this industry, as well as to the ongoing development and improvement of the technology. Alibaba currently provides equipment that is cutting edge in terms of innovation and technology. Thousands of Alibaba rope braiders are currently in use around the globe, creating ropes for a virtually limitless number of applications.

Features

- High-speed braiding machines can produce different standard products. Three times faster than a typical braiding machine, simplified adjustment.

- Particular care is taken to safeguard each spare part and maintain better quality.

- A mechanism for automatic feeding of materials into automatic production

- The machine runs smoothly and has a long life because the main parts use long-lasting mechanical skills.

- Auto yarn breakage alarms are easy to install and operate, low wearing, and require little floor space.

- Auto-production is possible when used with a bobbin winder.

- For round rope, multiply the bobbin (double spindle) number by two.

How Are Ropes Made?

Long solid threads called fibers are the basic building blocks of rope. Both natural and synthetic fibers made from oil can be found in these fibers. The stems of plants contain natural fibers. Naturally, these fibers originate from plants; they include hemp, manila, coir, sisal, nylon, and propylene, which are derived from oil. Typically, yarns are created first from the fibers. Three or four strands are then twisted together after the yarns have been twisted to form a strand to create a rope. Historically, hand spinning was used to accomplish this. Yarns were spun on machines in the spinning mill beginning in the 1850s. The spun yarns were wound into bobbins by machines.

Benefits of Braiding Machine

The even weight distribution throughout the braided material improves impact resistance, which is one of the benefits of braiding. In braided structures, interlaminar adhesion allows the layers to move together, preventing cracks.

Conclusion

Three or more strands of a material, such as thread or wire, are combined by a braiding machine to create a rope-like shape. Strong tensile ropes can be used for various tasks, including dragging and lifting. Humans have used Alibaba ropes for at least 40,000 years, and their advantages throughout human history cannot be overstated. They can be produced using synthetic fibers or natural fibers derived from plants. Ropes and braiding are used in a variety of commonplace fields. This report focuses on designing a rope-braided machine while considering all design constraints. You can get braiding machine with advance features from Alibaba. So, what are you waiting for go and get the one that fulfill your requirements.