Exploring the Manufacturing Process of Wholesale Sublimation Blanks

Wholesale sublimation blanks are crafted through a unique process designed to prepare them for high-quality, durable prints. These blanks are specially manufactured to accept sublimation ink, ensuring vibrant colors and long-lasting designs. Understanding how these blanks are made offers insights into quality control, material choices, and the properties that make certain blanks ideal for sublimation printing.

The Role of Polyester in Wholesale Sublimation Blanks

The foundation of high-quality wholesale sublimation blanks is its material. Polyester, or polymer-based materials, are essential as they enable the sublimation ink to bond on a molecular level when heat is applied. Unlike cotton or natural fibers, polyester holds sublimation ink permanently, which makes it the preferred material for items like t-shirts, mugs, and coasters.

In many cases, items that would not typically contain polyester—such as ceramic mugs or phone cases—are coated with a thin layer of polyester-based material. This coating is applied to items designed to withstand high temperatures and allows for consistent, vivid sublimation results across a range of products.

Key Steps in the Manufacturing of Wholesale Sublimation Blanks

Producing wholesale sublimation blanks involves several precise steps to ensure consistency and quality:

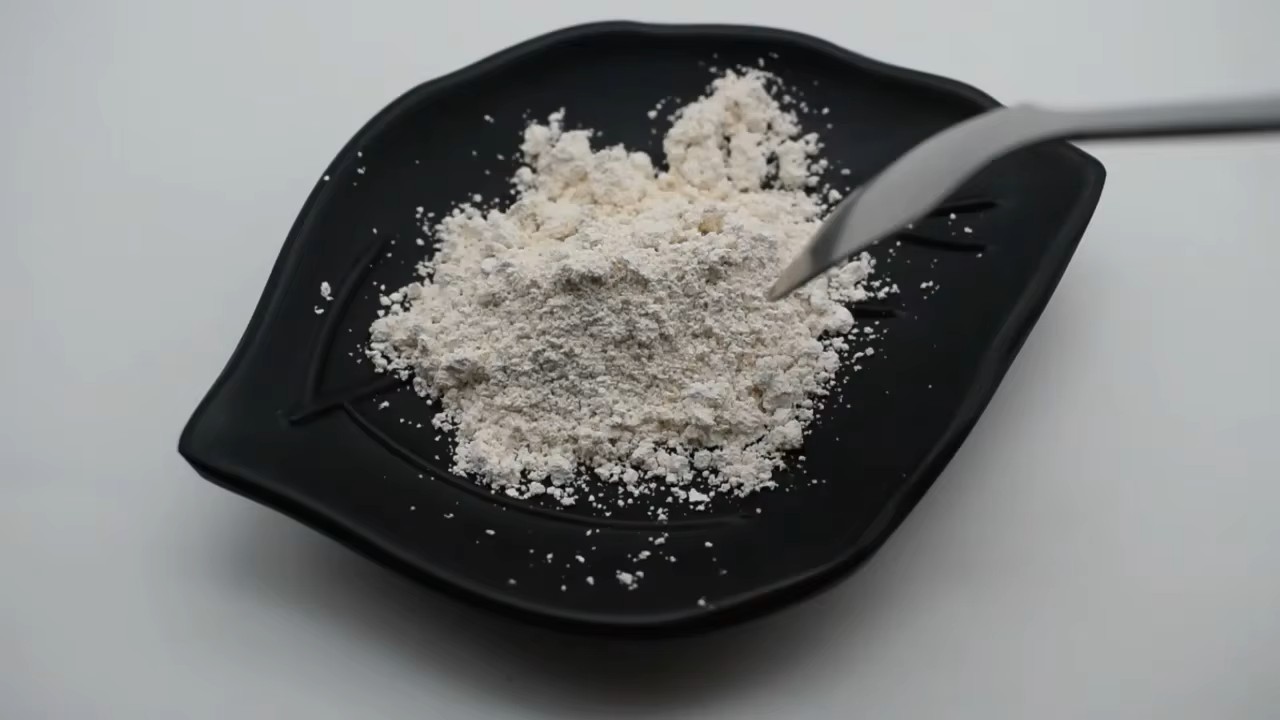

- Material Selection and Preparation: For items like apparel, polyester blends are chosen and prepared based on specific thickness, thread count, and weight to ensure a smooth surface for printing. For non-fabric items, a polyester coating is prepared separately and later applied to items like mugs or metal plates.

- Polymer Coating Application: Non-polyester items are dipped, sprayed, or brushed with a polyester or polymer coating. The coating thickness and quality are tested for uniformity to ensure consistent print quality, regardless of item shape or size.

- Heat Resistance Testing: Each blank undergoes heat testing to ensure it can withstand the sublimation printing process, which involves exposure to temperatures up to 400°F (200°C).

Quality Standards in Wholesale Sublimation Blanks Production

Each blank goes through rigorous testing stages to maintain high standards, especially when produced in large quantities. Quality control often involves:

- Color Testing: Some manufacturers use test prints to check the vibrancy and adhesion of sublimation ink on the blanks, ensuring that each blank will produce high-quality results when printed.

- Durability and Scratch Testing: Items such as phone cases and keychains go through scratch testing to ensure that the print will remain vivid and intact despite everyday wear.

- Adhesion Testing: Adhesion tests check the bond between sublimation ink and the blank’s surface. Properly manufactured sublimation blanks prevent ink from peeling, fading, or cracking over time.

Future of Wholesale Sublimation Blanks

With increasing interest in sustainability, the industry is likely to continue developing biodegradable and environmentally friendly sublimation blanks, appealing to eco-conscious consumers.

Additionally, with the rise of customized tech accessories, the sublimation industry is also expected to produce more blanks tailored for electronics, such as cases for newer smartphones, tablets, and wireless devices.

Another emerging trend is the use of augmented reality (AR) to showcase sublimation products online, which allows consumers to visualize how a design will appear on various blanks before purchase.

Conclusion

From the use of polyester materials and coatings to innovative testing and quality control standards, the production of wholesale sublimation blanks plays a crucial role in ensuring the quality of final printed products. As technology continues to advance, the sublimation blank industry is likely to see even more improvements, meeting the needs of creators and consumers alike in a rapidly growing market.