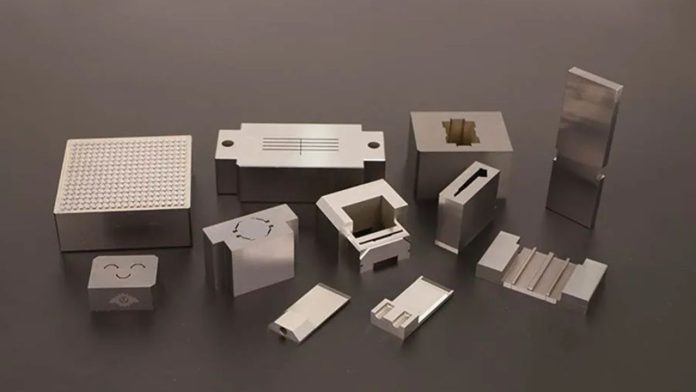

Carbide punches are also very important in stamping processes in most industries, like the automotive industry, electronics industry, medical devices, and micro-components manufacturing. They are chosen because of their long life, hardness, and wear resistance, which allows them to be used in high-precision and high-speed applications. Due to their high-performance needs, the production of a carbide punch is a very stringent and technical process. The paper describes the manufacturing process of Tungsten Carbide Punches as well as the major factors that would be required in order to attain the desired precision.

Knowledge: Carbide Punch Materials

The process of quality carbide punching is based on the selection of an appropriate grade of tungsten carbide. KD20, RD50, H40S, GA20, RG3, and CD650 are all carbide grades with varied degrees of hardness and toughness. To achieve the right grade, it is necessary to select the shape of the punch, anticipated load, material to stamp, and anticipated tool life.

An example is that square punches are normally punched with KD20 and round punches with H40S. With the appropriate carbide material, it is hoped that the punch will be sharp, repeatable, and last long, even when stamping operations are demanding.

High Accuracy Design and Specifications

Each carbide punch starts with an elaborate design determining its size, tolerances, shape, and other special characteristics necessary to the stamping die. This phase of the design is essential since carbide is very hard, and once the machining process begins, it becomes hard to make any changes, and any changes made are often expensive.

Technical drawings and CAD models are needed by the engineers to define specific requirements. These requirements dictate all production processes, making the integration of the die set easy and long-term operation of the die in the high-speed manufacturing process.

Preparation of Materials

Tungsten carbide blanks are used in the manufacturing process. These blanks are of different sizes and shapes, according to the design of the punch. Since tungsten carbide is harder in comparison to most cutting tools, rough cutting is performed with diamond-coated blades or abrasive cutting machines.

This measure is taken to make certain that the blank is safely located on the grinding table, without developing cracks and internal stress that could potentially impact the punch during stamping.

Machining: Cutting-Edge Grinding

Conventional milling and turning machines are unable to machine carbide. Rather, there are special abrasive machining techniques to provide the necessary accuracy.

Optical profile grinding (PG) is applied in the shaping of finer curves and shapes of the contours. The machine adheres to the toolpaths created by CAM and enables the punch to make tight tolerances.

Precision surface grinding (SG) is the flattening, sharpening, and reduction to final dimensions, by diamond grinding wheels, of surfaces and edges of a part.

Wire EDM (Electrical Discharge Machining) is a method employed to make sharp angles, minute features, and complex shapes, which cannot be made by grinding alone. It employs electrical sparks to mold the carbide without using any physical contact, thus making it very accurate and clean cutting. These two types of technology allow the manufacturers to come up with punches that are sensitive, consistent in size, and durable.

Surface Improvement and Fine Finishing

After the machining, it is subjected to the finishing procedures, which enhance the quality of the surface of the punch. The processes used are polishing, lapping, and edge refining to remove micro-defects and enhance the smoothness of contacting surfaces. Fewer scars will minimize friction during stamping and have a longer punch life.

Micro-precision punches in connector and semiconductor stamping are sometimes finished at the mirror-level, and any small defects may be very critical to the accuracy of the product. In order to enhance wear resistance even more, high-tech punches can be coated. Popular finishes are DLC (Diamond-Like Carbon), TA-C, and WC-C. These finishes help lower friction between the tool and the piece, decrease heat concentration, and greatly increase the life of the tool- particularly in high volume stamping conditions.

Quality Inspection and Control

An inspection is conducted on every carbide punch to be shipped to guarantee that it meets the necessary tolerances and performance criteria. The dimensional accuracy is verified with the help of the TRIMOS height gauges and 2.5D measurement projectors. Also tested are surface finish, hardness, and profile accuracy.

The strict quality control is what guarantees that the punch works reliably, has similar dimensions, and will last longer in the industry.

Conclusion

The manufacturing of precision carbide punches involves skills, the availability of materials, advanced machining, and attention to quality. Design and the choice of carbide grade, all the steps of grinding, finishing, and coating contribute greatly to the process of attaining accuracy and durability. Combining all these factors, one will have a high-performance carbide punch that can produce uniform output in the most challenging stamping processes.